|

The gland strip for doors and windows of subway and high-speed trains is molded uninterruptedly with micro wave curing process. The surface is smooth and trim. According to the drawings of designers and customers, the strip is made into frame directly with the help of computerized rubber jointing machine. In this way, the water seepage and the water leakage are eliminated at the joint. The strip is made of EPDM, which is anti-ageing, hot resistant, cold resistant, elastic and compression deformation resistant.

■.Product Standard

1、DIN5510-2(Germany)《Orbital Vehicles Fire protection Material And Part Combustion characteristic And Burning Concomitance Phenomenon Classification, Request And Inspection procedure》

2、DIN5514(Germany)《Orbital Vehicles Use Material Elastomer Concept, Material Explanation》

3、NF F 16-101(France)《Rolling stock Serodynamic combustion Performance - Choice of material》

4、NF F 16-101(France)《General Railroad Facility Material Compact Rubber Extrusion》

5、BS 6853-1999(England)《Orbital Vehicles Design And Structure Fire protection Request》

6、TB/T 2402-93 《Railroad Passenger train Nonmetallic material Being flame-resistant Request》

7、TB 1964-87《Passenger train Windows and doors Use Packing Inspection procedure》

8、TB 1444-83《Diesel locomotive Rubber Engineering factor》

9、HG/T 3088-1987《Vehicles Windows and doors Rubber Packing》 |

|

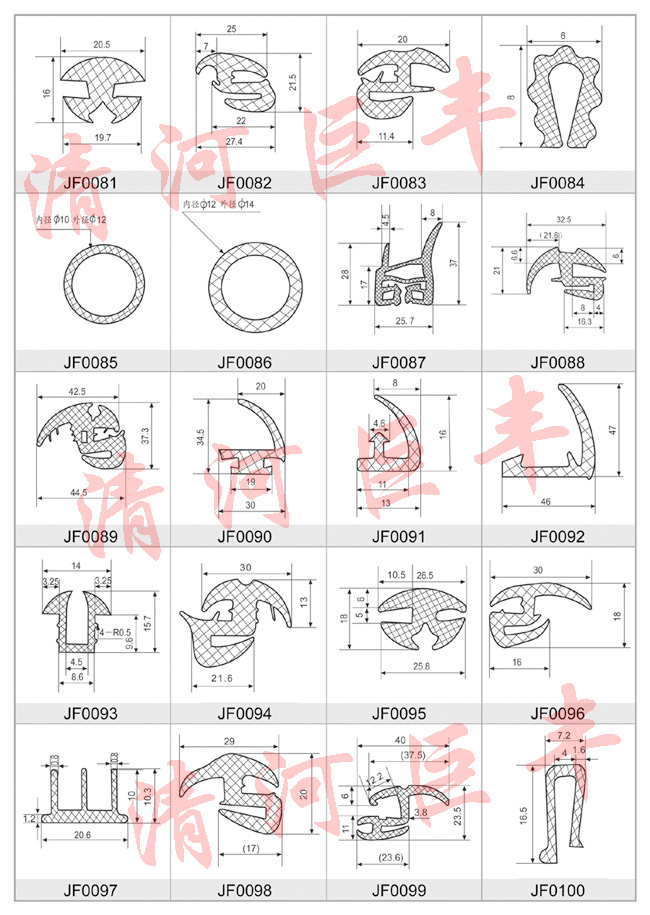

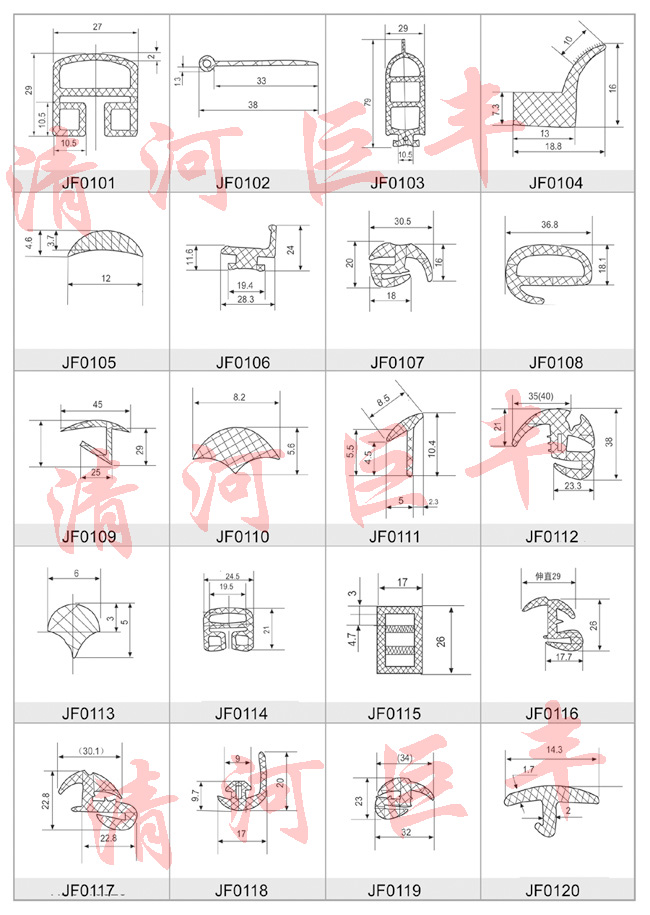

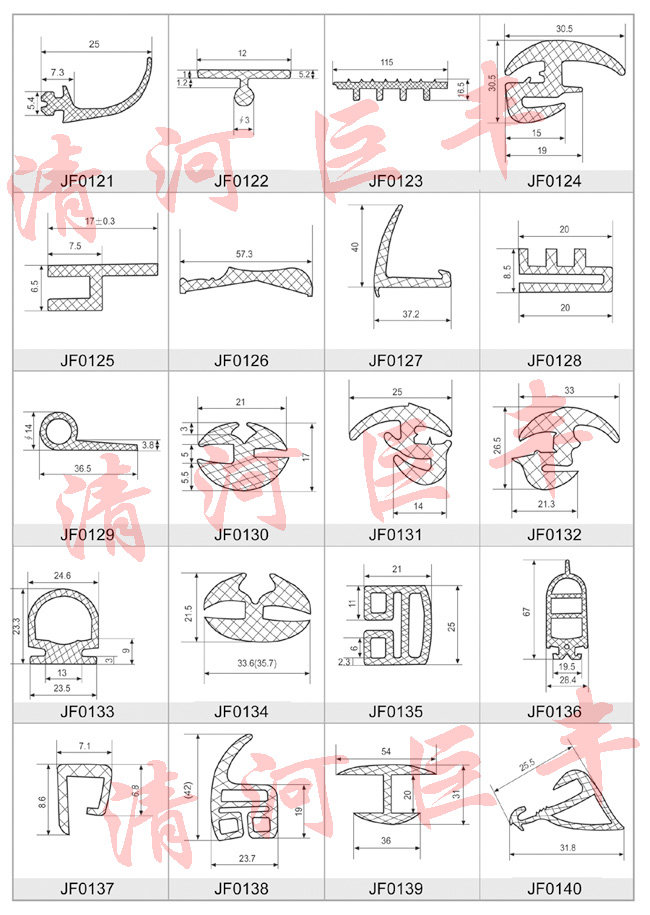

Product detail information

Product detail information Hebei Qinghe Jufeng Rubber Seal Co., Ltd., Contact

Hebei Qinghe Jufeng Rubber Seal Co., Ltd., Contact